The success of pharmaceutical industry in the current era is really very much surprising but if you want to know the real secret behind it then you have to move deeper inside. Turnkey barrier isolator systems are highly responsible for the advancement of modern pharmaceutical industry and this fact has already been proved by medical experts.

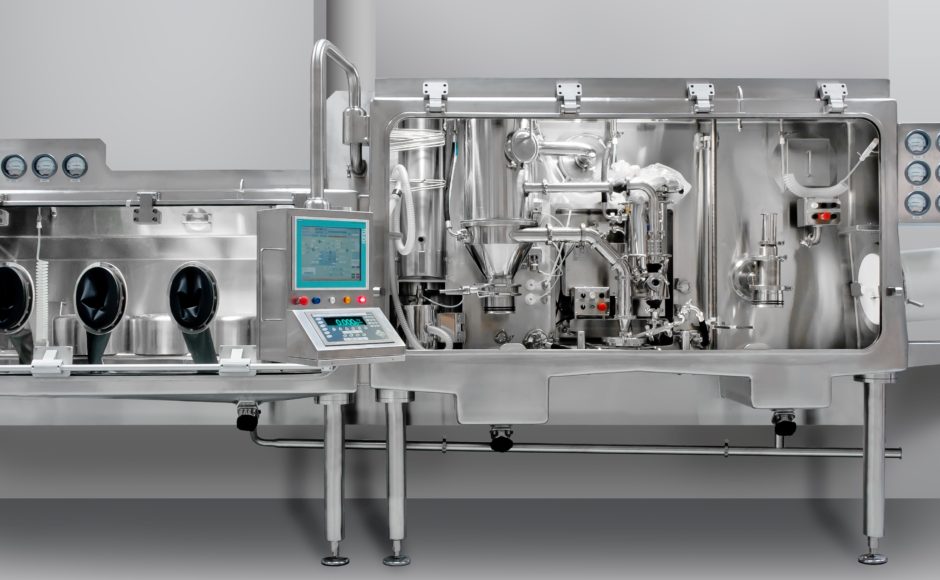

Two separate devices are found into force out here, one is isolator and another is RABS (Restricted Access Barrier). Hygienic and tidy ambience can be now easily maintained with the use of these two outstanding devices. These devices are fully automated and you just have to make the necessary setting changes as per requirement.

Key benefits:

Turnkey barrier isolator systems have really contributed a lot in the success of the pharmaceutical industry. To be precise, these systems are the life support for the concerned industry. Some of the most outstanding advantages that can be derived from these high end systems are as follows:

- Patient’s safety: Since patient safety is one of the leading concerned of pharmaceutical industry therefore keeping that in mind these systems have been introduced. Drugs of different kinds can be now manufactured with great safety just due to the presence of these systems. Drugs are being thoroughly sterilised so that unwanted contaminants can be kept away. Contaminated drugs create greater complications or side effects in patient’s body. Drugs are now being manufactured at completely safe and clean ambience. Clean rooms are being used in this respect so that contaminations especially during filling procedure can be efficiently prevented. Aseptic quality level can be easily controlled or regulated by these innovative systems. This is how drug making procedure has become much more flexible these days.

- Sterile rooms: Now, creating and maintaining sterile units have become much easier with the commencement of this amazing barrier technology. Initially it was not that easy to prepare sterile rooms for drug making but this issue has been resolved with barrier isolator system. Sterile products especially inhalers or ophthalmic drugs and parenteral drugs can be now efficiently processed without entertaining any contaminants just because of this technology. Microbial impurities are kept away at the time of drug processing. This barrier system is basically installed within drug processing rooms only in order to make the drugs sterilised in a proper way.

- Easy production of sanitised equipment: Now, different kinds of medical equipment can be produced with proper sterilisation due to the involvement of the concerned barrier system. Contamination levels are being reduced to a great extent so that sterilised equipment can be manufactured smoothly and safely. Rooms are not only sanitised but the equipment is also being sanitised thoroughly. Since the medical tools are sent to different hospitals or medical centres therefore the manufacturers need to maintain a perfect sanitisation level so that patients can stay protected and the procedures with these tools can be conducted safely. This is how ISO safety standards are being maintained at the time of manufacturing medical tools.

If you analysed properly then you will come to discover this fact that nowadays drug making expenses have been reduced at great levels just because of the usage of Turnkey barrier isolator systems. In fact, the manufacturers are offering a cheaper rate to the purchasers as well.